Researchers in Australia have developed a simplified residual network-based architecture method to filter out noise from electroluminescence images of PV modules. The proposed technique reportedly enhance the accuracy and efficiency of automated inspection systems for utility-scale PV plants.

A group of scientists led by researchers from the University of New South Wales (UNSW) in Australia has developed a novel deep-learning method for denoising outdoor electroluminescence (EL) images of PV modules.

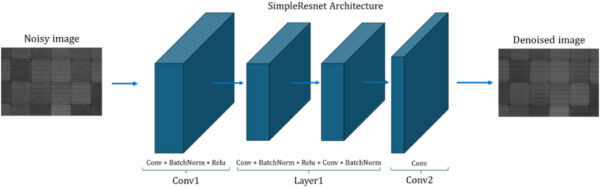

Dubbed SimpleResNet, the novel method is based on a simplified residual network (ResNet)-based architecture, which utilizes residual connections to enable neural networks to learn more effectively.

“Through the use of a custom computer vision model, featuring a deep convolutional neural network architecture, we are able to improve the quality of denoising for imaging datasets, in particular by maintaining important high-contrast image features crucial for diagnostic analysis,” corresponding author Brendan Wright told pv magazine. “The performance of our methodology exceeds prior attempts and more general denoising algorithms.”

The novel methodology consists of an input convolutional layer with eight filters, a single residual block, and an output convolutional layer. The residual block, in turn, contains two 3 × 3 convolutional layers with eight filters each. The model was trained, validated, and tested on 627 images, with a 7:2:1 ratio.

The dataset consisted of grayscale luminescence images of full-cell and half-cell monocrystalline PV modules, captured indoors at a bias of 100% and 10% of the module’s short-circuit current. Three types of noises – Gaussian, Poisson, and salt-and-pepper – were added to those images, alone and together, using mathematical models. Finally, noisy-clean image pairs were combined for the use of the model.

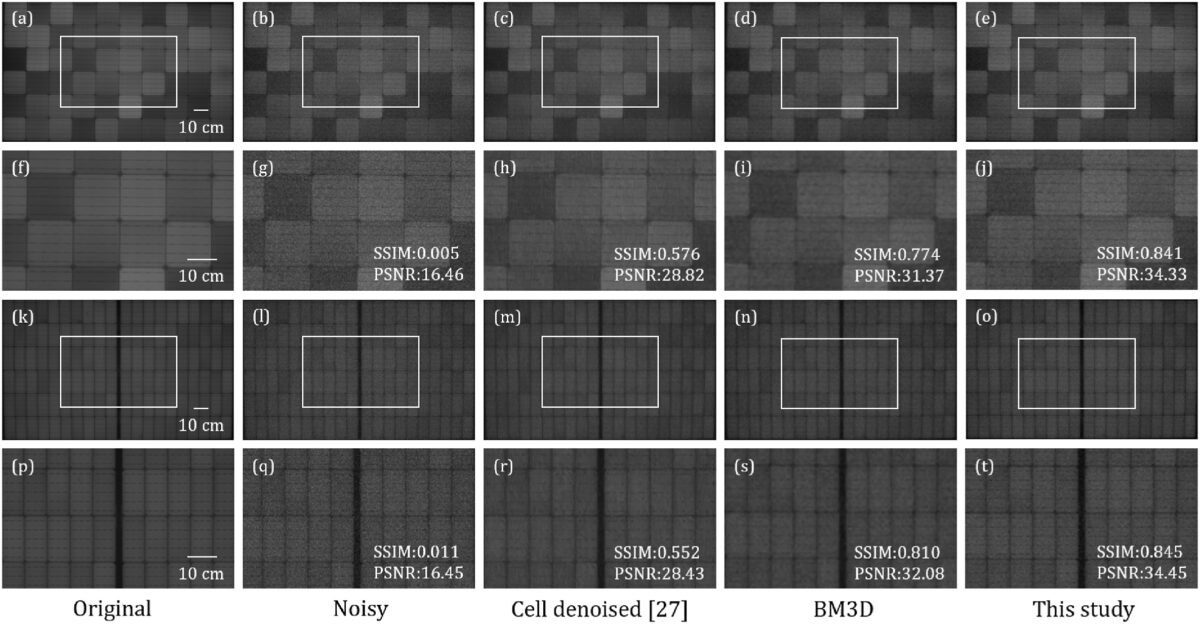

Image: University of New South Wales, Solar Energy Materials and Solar Cells, CC BY 4.0

“For benchmark comparison, the BM3D algorithm, a state-of-the-art traditional denoising method, was applied. The noise standard deviation parameter in BM3D, which controls the strength of denoising, was set to 160/255 for optimal performance,” said the scientists. “Additionally, results were compared with the ResNet34-based cell-level denoising model. Although this model was designed and trained for individual PV cells, it was adapted here to process full module images, highlighting the urgent need for dedicated module-level solutions.”

The SimpleResNet architecture was found to demonstrate better denoising performance than the benchmarks. It has achieved a mean peak signal-to-noise ratio (PSNR) value of 33.56 dB and a structural similarity index measure (SSIM) value of 0.84. BM3D, on the other hand, achieved 31.48 dB and 0.80, respectively, while the cell-level denoising approach achieved 28.42 dB and 0.62, respectively. “These developed capabilities contribute to enhancing the accuracy and efficiency of automated inspection systems for utility-scale PV plants,” the academics noted.

The analysis also showed that the method’s processing speed was under 0.2 seconds per image. “We achieve a dramatic computation time/cost benefit when using this more focused model, reducing the single-image-processing time to below 1 second, an order of magnitude improvement compared to the reference BM3D algorithm, thereby making this methodology feasible for real-time processing applications,” added Wright.

“We intend to continue optimizing the performance of this class of models, through improvements in architecture and training methods, but also to focus on generalization and application to additional diagnostic imaging techniques, including infra-red and photoluminescence imaging, where we have already seen promising results,” concluded Wright. “We expect our general machine learning methodology to enable significant advances in solar module monitoring and analysis, having a positive and practical impact on the industry.”

The new technique was presented in “Robust denoising methodology for outdoor electroluminescence images of photovoltaic modules using deep learning,” published in Solar Energy Materials and Solar Cells. Scientists from the University of New South Wales in Australia and the Technical University of Denmark collaborated on the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Source link