Australian researchers have developed electrolysis systems that use urea sourced from urine and wastewater to generate hydrogen at “significantly lower” energy costs than traditional water-splitting methods.

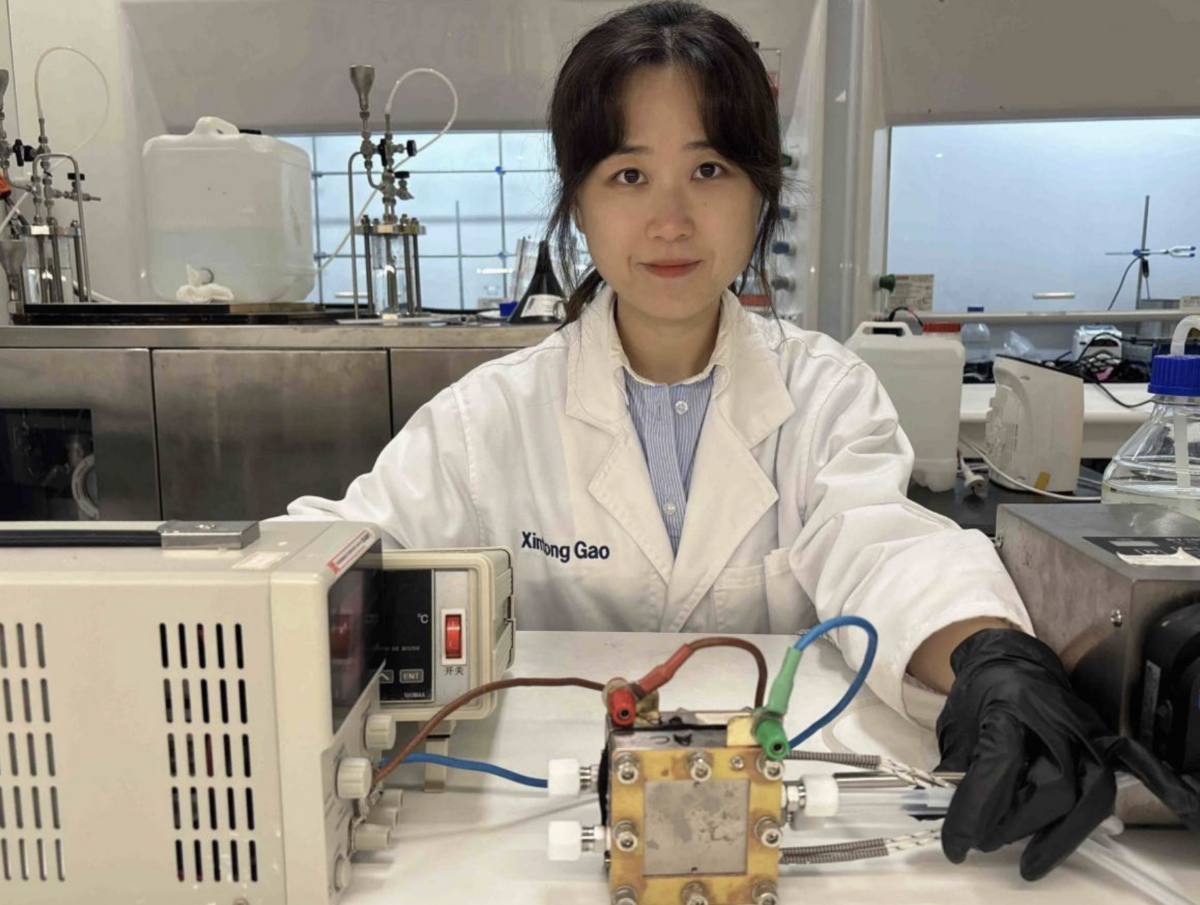

Researchers from the University of Adelaide and the Australian Research Council Centre of Excellence for Carbon Science and Innovation (COE-CSI) have created two electrolysis systems that harness urea found in urine and wastewater to produce hydrogen while reducing electricity consumption by up to 27% compared to water-based hydrogen production.

COE-CSI Chief Investigator Professor Yao Zheng said the approach not only makes green hydrogen economically competitive with fossil fuel-derived alternatives but also creates an elegant solution for wastewater treatment.

“While we haven’t solved all the problems, should these systems be scaled up, our systems produce harmless nitrogen gas instead of the toxic nitrates and nitrites, and either system will use between 20–27% less electricity than water-splitting systems,” he said.

Hydrogen is typically generated through the use of electrolysis to split water into oxygen and hydrogen. The research team said this process is “cost prohibitive” and energy intensive, requiring 1.23 V to trigger the reaction while they were able to split urea, which as a hydrogen carrier has a lower thermodynamic decomposition barrier than that of water, with just 0.37 V.

In their first study, the team employed a membrane-free electrolysis system powered by a copper-based catalyst with pure urea as the feedstock. That urea was produced through the Haber-Bosch ammonia synthesis process. To avoid this energy-intensive and carbon-emitting process, a second system was designed to utilise urea found in urine.

“We need to reduce the cost of making hydrogen, but in a carbon-neutral way,” Zheng said. “The system in our first paper, while using a unique membrane-free system and novel copper-based catalyst, used pure urea, which is produced through the Haber-Bosch ammonia synthesis process that is energy intensive and releases lots of CO₂.”

“We solved this by using a green source of urea, human urine, which is the basis of the system examined in our second paper.”

While a promising source of urea, urine brings its own challenge. It contains chloride ions that can trigger unwanted chemical reactions during electrolysis. These reactions produce chlorine gas that corrodes the system’s anode and undermines long-term functionality.

To address this, the researchers’ second system features a chlorine-mediated oxidation mechanism that redirects the reaction pathway using platinum-based catalysts supported on carbon.

The researchers said the approach not only protects the anode but also maintains efficient hydrogen production from urine, adding the platinum-based system achieves electricity consumption as low as 4.05 kWh per cubic meter of hydrogen, outperforming traditional water electrolysis (4.70-5.00 kWh).

“The financial implications of this breakthrough could transform the green hydrogen landscape,” they said, adding that calculations suggest hydrogen produced through their system costs less than traditionally extracted “grey” hydrogen from fossil fuels.

“The industrial-scale membrane-free electrolyser based on this system successfully reduces hydrogen production cost to USD 1.81 per kilogram ($2.79), lower than those of grey hydrogen, and below the United States Department of Energy’s 2030 technical target of USD 2.00-2.50 ($3.08-$3.85) per kilogram,” the researchers said.

The team is now working toward building full membrane-free systems that both recover green hydrogen and remediate nitrogen-rich wastewater. It also acknowledged that the use of platinum as a catalytic material is unsustainable and is aiming to develop non-precious metal alternatives.

The research is published across Angewandte Chemie International Edition and Nature Communications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Source link