The flexible, automated production allows Swiss project partner Freesuns to produce its newly developed matrix shingle roof tiles on a pilot scale before moving into mass production.

The Fraunhofer Institute for Solar Energy Systems ISE has teamed up with Swiss solar roof manufacturer Freesuns to establish a pilot line for PV roof tiles at its Module Technology Evaluation Center (Module-TEC) in Freiburg as part of its Sustainable Photovoltaics Integration in Buildings and Infrastructure (SPHINX) research project.

The flexible, automated production allows Freesuns to produce its newly developed matrix shingle roof tiles on a pilot scale before moving into mass production. The production line will manufacture a total of 4,000 solar roof tiles using the matrix shingle technology. Since March 2025, the company has produced the first 800 and is currently installing the roof systems into five existing buildings in Switzerland.

“By manufacturing the first matrix shingling Freesuns solar roof tiles in Fraunhofer ISE’s Module TEC, we can collaborate on the production development and demonstrate the great advantage of matrix technology,” said John Morello, founder and CTO of Freesuns. “Our focus in developing this product is on applications for existing buildings, especially those listed as historic structures.”

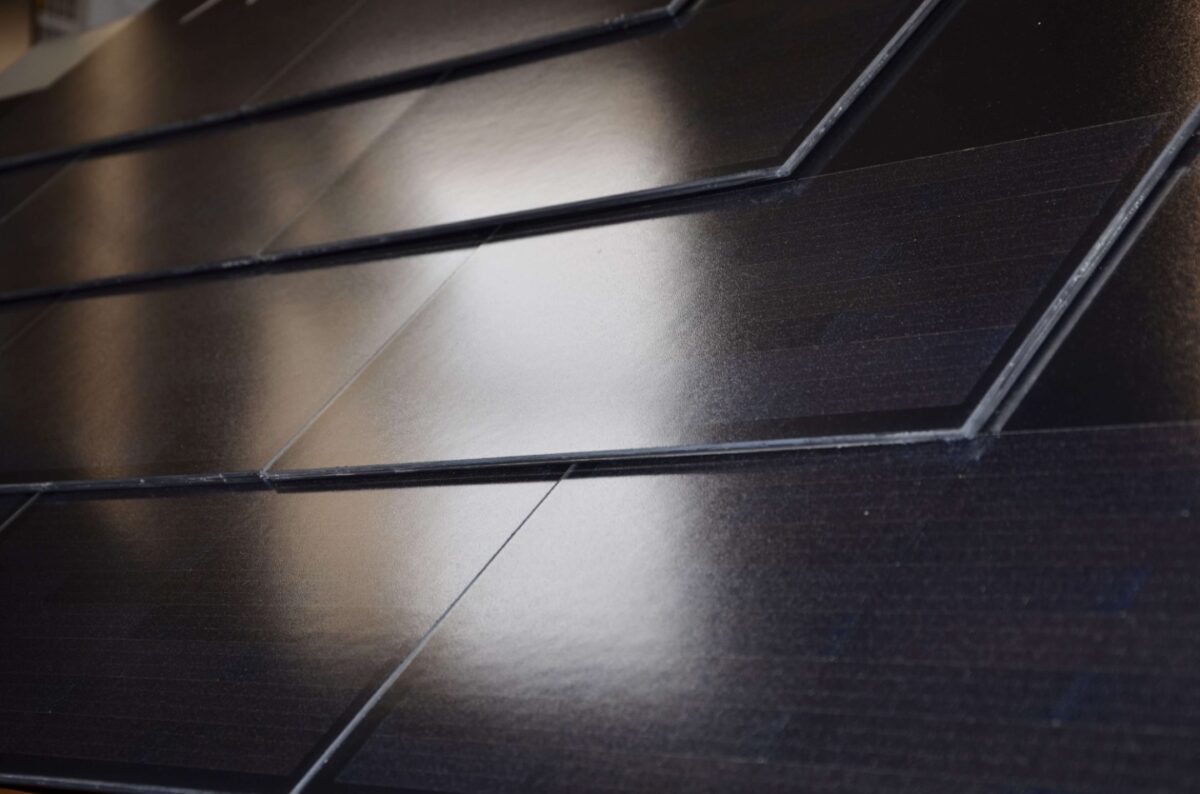

The 450 x 510 mm solar roof tile consists of a glass-glass module with TOPCon solar cells connected in a shingle matrix, with various color options available.

In shingle technology, the solar cell strips are connected to strings using electrically conductive, lead-free adhesives and arranged in an overlapping pattern, like roof shingles. According to Fraunhofer ISE, PV modules produced in this way are more efficient because the currents of the solar cell strips are smaller than in half-cell modules, the collector bars of the solar cells are covered with active cell surface, and there are no gaps between the solar cells of a string. Fraunhofer ISE adds that the matrix shingle concept it developed goes one step further: the shingled solar cells are also arranged in a staggered pattern. “This enables complete, homogeneous coverage of the entire module surface, making matrix shingle modules around 4% (relative) more efficient than conventional half-cell modules with wire interconnection.”

“Matrix shingle modules are predestined for integrated applications, especially in building facades and, as here, as photovoltaic tiles on roofs,” said Fraunhofer ISE project manager Torsten Rößler. “This is precisely where maximum space utilization, shading tolerance, and attractive aesthetics are important.”

The matrix shingle technology is characterized by a very high tolerance to partial shading and its arrangement allows the electricity to flow around the shaded areas, so that, depending on the partial shading, twice the power can be generated compared to conventionally interconnected PV modules.

In the SPHINX project, a consortium of European PV manufacturers and research institutions has set itself the goal of developing cost-effective, rapidly deployable building-integrated photovoltaic (BIPV) elements using innovative matrix shingle technology. These modular, prefabricated elements will vary in size and functionality and will be available as lightweight construction, semi-transparent PV tiles. Thanks to its flexible configuration, the pilot production line at Fraunhofer ISE’s Module-TEC can implement the various prototypes and produce initial small series in an industry-oriented manner.

The new solar roof tiles are on exhibit at The smarter E Europe trade show in Munich from May 7 to 9 at the Fraunhofer ISE booth in Hall A1.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Source link